Supply Chain

Distribute Your Product to the Right Locations Based on Demand, From the Initial Allocation Through Final Replenishment.

Know What to Move, Where to Move It, And When.

Churchill’s Demand Forecasting solutions help Supply Chain leaders anticipate seasonal demand, allocate inventory with confidence, and replenish based on data — not guesswork. With advanced AI models built for Seasonality, Allocation & Sell-Through, and Replenishment, we help you keep inventory lean, responsive, and aligned with business objectives.

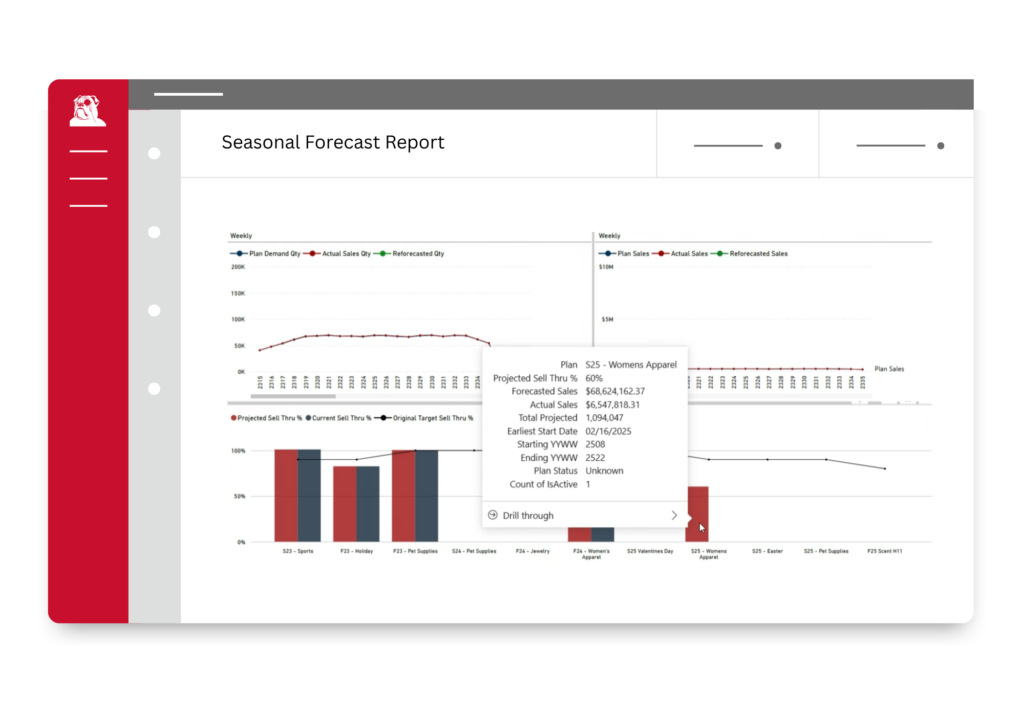

Seasonality

Predict demand with precision to maximize seasonal performance and minimize waste

Allocation & Sell-Through Forecasting

Make smarter initial allocations and in-season inventory moves

Inventory Replenishment

Shift from reactive strategies to proactive planning — keeping shelves stocked and inventory balanced

Seasonality

Churchill’s Seasonality solution helps supply chain teams generate accurate seasonal profiles through our proprietary Profile Cluster Builder™ (PCB). By analyzing item attributes and category behavior, PCB supports localized forecasting that aligns inventory with future demand across the product lifecycle. This enables more efficient seasonal allocations, reduces overstock and early sellouts, while ensuring that assortments are optimized down to the store level.

- Build seasonal profiles at every level of the item and store hierarchies

- Improve assortments by getting the right mix of products to achieve business objectives

- Update profiles on a regular basis as consumer demand changes

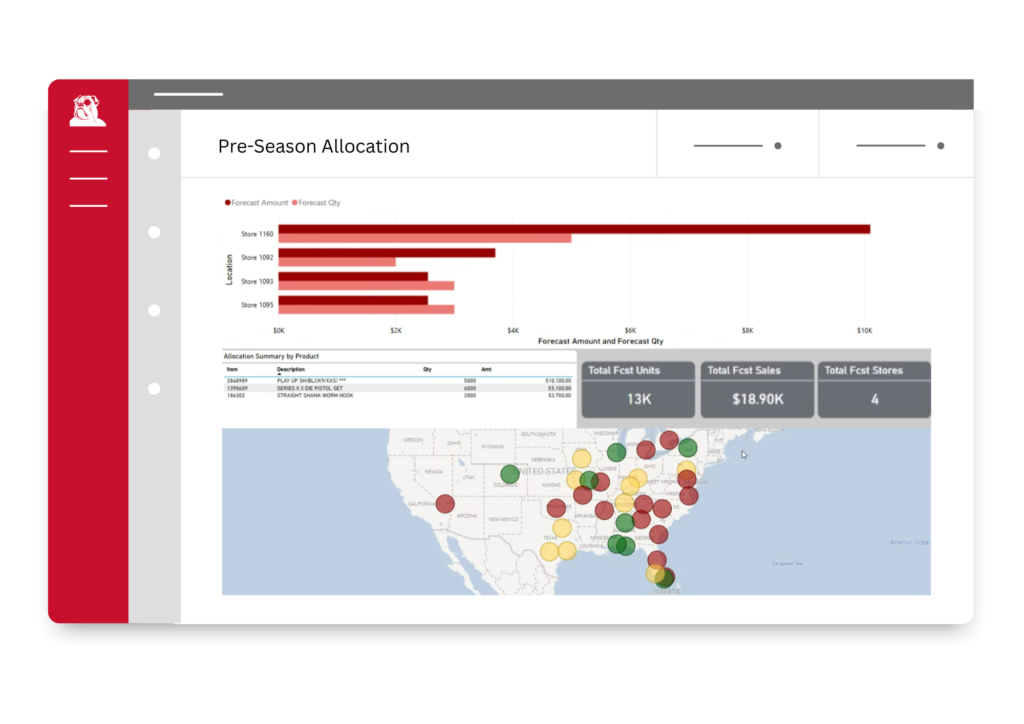

Allocation

Churchill’s Allocation solution leverages the Short Life Cycle Demand Forecaster™ (SLC) to optimize initial allocations and in-season inventory decisions. By forecasting item-level demand at the store level, retailers can minimize stockouts, reduce markdowns, and optimize inventory at every location.

- Higher Confidence in First Allocations

- Localized Inventory Optimization

- Demand-Based Redistribution During Season

- Minimized Stock Imbalances Across Stores

Inventory Replenishment

Churchill’s Inventory Replenishment forecasting solution transforms replenishment into a proactive, demand-driven process. Purpose-built for large, complex retail networks, it uses the Replenishment Demand Forecaster™ (RDF) to generate accurate, store/SKU-level forecasts and model stock targets. By aligning replenishment decisions with true demand signals, it reduces excess stock, prevents stockouts, and improves inventory turnover.

- Demand-Aligned Reorders

- Store/SKU-Level Precision

- Improved Inventory Turnover

- Scalability for Complex Retail

- Reduced Manual Intervention

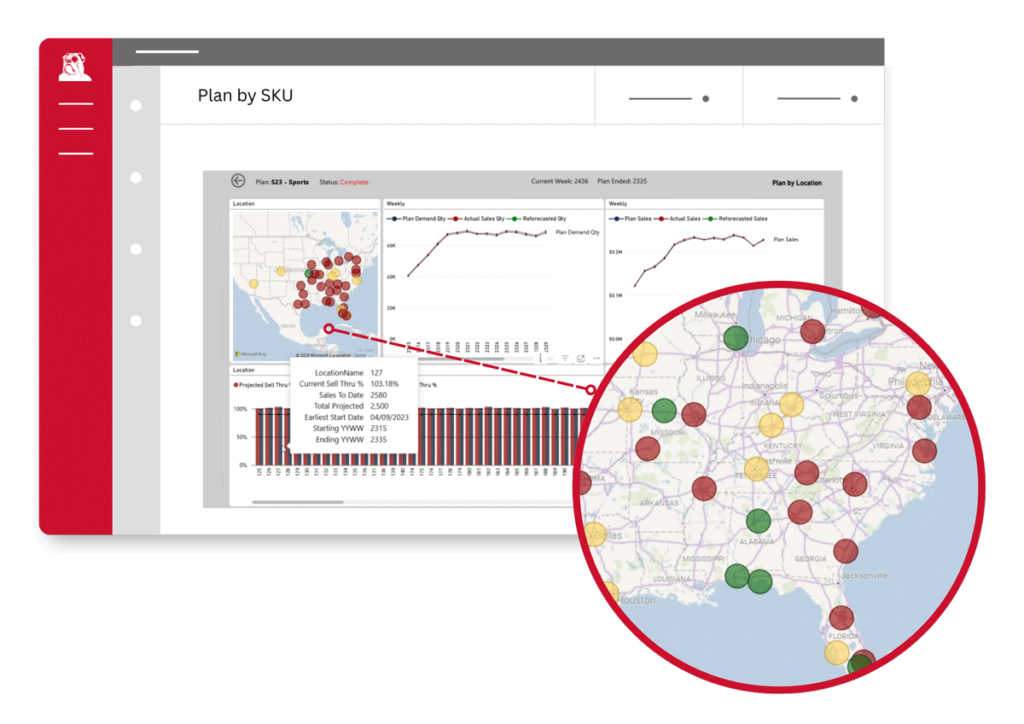

Sell-Through Forecasting

Churchill’s Sell-Through Forecasting solution, powered by the Short Life Cycle Demand Forecaster™ (SLC), helps retailers maximize every selling window by predicting demand at the SKU and store level. Churchill enables retailers to forecast what will sell, where, and when — especially for perishable and short lifecycle products.

- More Predictable Sell-Through Performance

- Smarter Use of Limited Inventory

- Faster Mid-Season Adjustments

- Targeted Markdown Strategies

What’s Really Holding Back Your Inventory Performance?

Explore how AI-based Demand Forecasting improves three critical Supply Chain functions: Seasonality, Allocation & Sell-Through, and Replenishment. This eBook offers a practical breakdown of how AI helps reduce stockouts, cut excess, and keep your network aligned with demand.